應用實績 : 超低濃度氯線上監測儀 ULR CL17sc 於美國德州某半導體製造廠之純水監測應用

ULR CL17sc success at a semiconductors manufacturing facility in TX

Introduction 介紹

Ultrapure water for semiconductor, pharmaceutical, chemical, or beverage production has strict limits on presence of contaminants including oxidants or reducers. Incoming source water is usually chlorinated and undergoes dichlorination with either granulated activated carbon (GAC) or chemicals such as sodium bisulfite (SBS). Dechlorinated water flows through additional treatment, frequently involving RO filtration when the operators should maintain low levels of disinfectant, while not allow excess of oxidants to damage the membranes. It has been shown that prolonged exposure of RO filters to chlorine above 38 ppb (based on 1000 ppm-hr over 3 years) is detrimental to the membrane structure and integrity, while absence of the disinfectant promotes biogrowth and causes loss of recovery. To maintain this delicate balance, the operators must be able to accurately monitor chlorine concentration and addition of dechlorinating chemicals.

用於半導體、製藥、化學品或飲料生產的超純水對於污染物(包括氧化劑或還原劑)的存在有嚴格的限制。進水源水通常經過氯化處理,並使用顆粒活性碳 (GAC) 或亞硫酸氫鈉 (SBS) 等化學物質進行脫氯。脫氯水經過額外的處理,通常是逆滲透過濾,此時操作人員應維持低濃度的消毒劑,同時不讓過量的氧化劑損壞濾膜。研究顯示,RO 濾芯長期暴露於高於 38 ppb濃度的氯(根據 3 年 1000 ppm-小時)對膜結構和完整性有害,然而,不使用消毒劑會促進生物生長並影響膜的功能回復。為維持這種微妙的平衡,操作人員必須能夠準確地同時監測氯濃度以及脫氯化學品的添加量。

Ultrapure water for semiconductor, pharmaceutical, chemical, or beverage production has strict limits on presence of contaminants including oxidants or reducers. Incoming source water is usually chlorinated and undergoes dichlorination with either granulated activated carbon (GAC) or chemicals such as sodium bisulfite (SBS). Dechlorinated water flows through additional treatment, frequently involving RO filtration when the operators should maintain low levels of disinfectant, while not allow excess of oxidants to damage the membranes. It has been shown that prolonged exposure of RO filters to chlorine above 38 ppb (based on 1000 ppm-hr over 3 years) is detrimental to the membrane structure and integrity, while absence of the disinfectant promotes biogrowth and causes loss of recovery. To maintain this delicate balance, the operators must be able to accurately monitor chlorine concentration and addition of dechlorinating chemicals.

用於半導體、製藥、化學品或飲料生產的超純水對於污染物(包括氧化劑或還原劑)的存在有嚴格的限制。進水源水通常經過氯化處理,並使用顆粒活性碳 (GAC) 或亞硫酸氫鈉 (SBS) 等化學物質進行脫氯。脫氯水經過額外的處理,通常是逆滲透過濾,此時操作人員應維持低濃度的消毒劑,同時不讓過量的氧化劑損壞濾膜。研究顯示,RO 濾芯長期暴露於高於 38 ppb濃度的氯(根據 3 年 1000 ppm-小時)對膜結構和完整性有害,然而,不使用消毒劑會促進生物生長並影響膜的功能回復。為維持這種微妙的平衡,操作人員必須能夠準確地同時監測氯濃度以及脫氯化學品的添加量。

Case Study 應用案例

A study conducted at a semiconductor facility in Texas was to help optimize their SBS feed control in the UPW preparation cycle.

美國德州某半導體廠進行一項優化超純水製備循環中控制SBS (sodium bisulfite,亞硫酸氫鈉) 投放量的應用研究。

A study conducted at a semiconductor facility in Texas was to help optimize their SBS feed control in the UPW preparation cycle.

美國德州某半導體廠進行一項優化超純水製備循環中控制SBS (sodium bisulfite,亞硫酸氫鈉) 投放量的應用研究。

Problem 問題

Dechlorination is used in the UPW preparation cycle for electronics, as well as other industries. The effects of GAC channeling and the issues related to underfeeding/overfeeding dechlorinating agents are well-known in the industry. The channeling and underfeeding SBS will manifest in creating an excess of chlorine attacking the RO membrane’s polymeric structure and causing irreversible damage. The overfeeding SBS leads to increase in biofilm formation due to the lack of biocide in the water. Besides the added cost and increase in biofouling, excess of sulfites leads to depletion of dissolved oxygen and proliferation of sulfur-reducing bacteria (SRB) in the water. SRB can cause microbially influenced corrosion, rotten egg smell due to formation of hydrogen sulfide (H2S), slimy coatings, and brown foaming. All these factors driving either excess, or lack of chlorine will diminish the RO membranes performance (flux) necessitating better monitoring and process optimization. Currently, RO feedwater monitoring and proportional addition of SBS is done with either grab sample analysis alone, or in its combination with continuous measurement of redox potential (ORP). Well known deficiencies of this approach do not make it the method of choice and such monitoring cannot provide effective optimization. There is a need for a simple and reliable instrumentation measuring chlorine directly, accurately and in a substantially continuous manner; able to monitor the exposure of the RO filters to chlorine to understand its impact on the membrane efficiency and life span.

脫氯工藝用於電子及其他行業的超純水製備循環。需要一款簡單且可靠的儀器以準確、直接、連續的方式監測純水的氯濃度;能夠監測逆滲透濾芯接觸氯的情況,以確實了解其對薄膜效率和使用壽命的影響。

Dechlorination is used in the UPW preparation cycle for electronics, as well as other industries. The effects of GAC channeling and the issues related to underfeeding/overfeeding dechlorinating agents are well-known in the industry. The channeling and underfeeding SBS will manifest in creating an excess of chlorine attacking the RO membrane’s polymeric structure and causing irreversible damage. The overfeeding SBS leads to increase in biofilm formation due to the lack of biocide in the water. Besides the added cost and increase in biofouling, excess of sulfites leads to depletion of dissolved oxygen and proliferation of sulfur-reducing bacteria (SRB) in the water. SRB can cause microbially influenced corrosion, rotten egg smell due to formation of hydrogen sulfide (H2S), slimy coatings, and brown foaming. All these factors driving either excess, or lack of chlorine will diminish the RO membranes performance (flux) necessitating better monitoring and process optimization. Currently, RO feedwater monitoring and proportional addition of SBS is done with either grab sample analysis alone, or in its combination with continuous measurement of redox potential (ORP). Well known deficiencies of this approach do not make it the method of choice and such monitoring cannot provide effective optimization. There is a need for a simple and reliable instrumentation measuring chlorine directly, accurately and in a substantially continuous manner; able to monitor the exposure of the RO filters to chlorine to understand its impact on the membrane efficiency and life span.

脫氯工藝用於電子及其他行業的超純水製備循環。需要一款簡單且可靠的儀器以準確、直接、連續的方式監測純水的氯濃度;能夠監測逆滲透濾芯接觸氯的情況,以確實了解其對薄膜效率和使用壽命的影響。

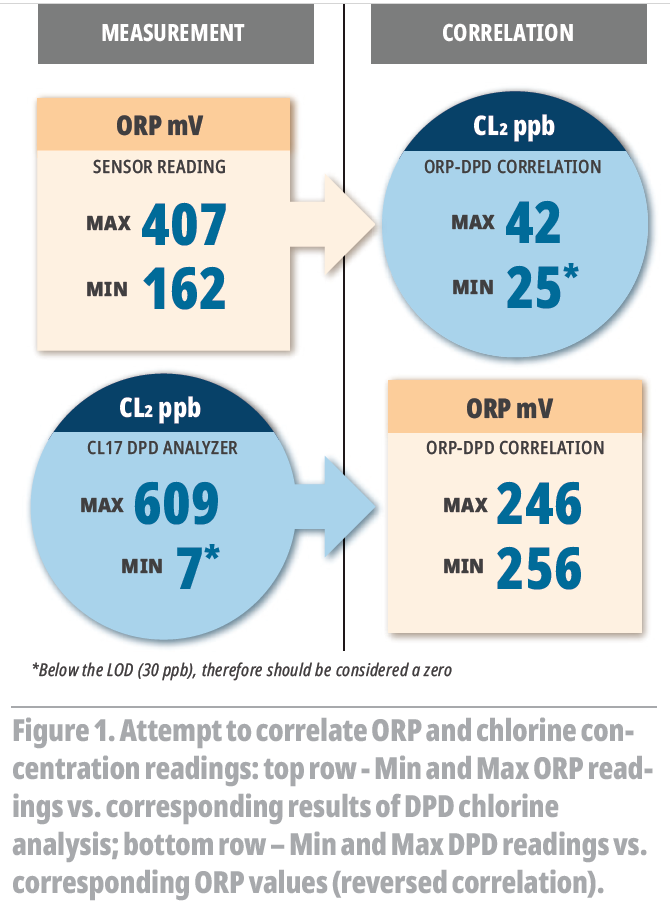

At the time of test, the UPW personnel relied on a standard CL17 analyzer and an ORP sensor to monitor and control dechlorination. The analysis of the time-stamped data showed that such correlation could not be used for process control. As follows from the data presented in Figure 1, logged extremums of the ORP readings did not match the max/min chlorine concentrations registered at the same time. ORP readings implied chlorine concentrations were between 25 and 42 ppb for the duration of the test whereas direct DPD chlorine analysis revealed an actual concentration range of 7 to 609 ppb between minimum and maximum. The latter correlation showed that the ORP probe was likely dysfunctional, given the reversed Min and Max correlated values (Figure 1). This observation highlights how dangerous it can be to rely solely on ORP readings to control dechlorination process.

Solution 方案

The need to maintain disinfectant residual to keep biofilm from growing excessively while at/below 38 ppb to ensure life expectancy of the RO membranes dictates the necessity to monitor residual chlorine accurately at such low levels. The Ultra-Low Range (ULR) CL17sc chlorine analyzer uses colorimetric method to measure total chlorine residual with unparalleled accuracy provided by the low limit of detection (LOD) of 8 ppb.

Accurate chlorine readings reported every 150 seconds will show a complete picture of dechlorination process, detect any excursions of chlorine above the set limit, and help to manage RO membranes properly. The Cumulative Chlorine Counter™ function of the analyzer calculates and shows on the screen how much chlorine has passed through the membrane at any given time. All this helps to ensure specified quality of RO feedwater of produced UPW, and by extension the quality of the manufactured products ranging from semiconductors to drinking water.

需要維持消毒劑殘留以防止生物膜在 38 ppb 或以下時過度生長,以確保 RO 膜的預期壽命,這顯示有必要在如此低的濃度下準確監測餘氯。超低濃度 (Ultra Low Range) CL17sc 氯自動分析儀 採用比色法測量總氯殘留量,其檢測下限 (LOD) 為 8 ppb,具有無與倫比的精確度。

Accurate chlorine readings reported every 150 seconds will show a complete picture of dechlorination process, detect any excursions of chlorine above the set limit, and help to manage RO membranes properly. The Cumulative Chlorine Counter™ function of the analyzer calculates and shows on the screen how much chlorine has passed through the membrane at any given time. All this helps to ensure specified quality of RO feedwater of produced UPW, and by extension the quality of the manufactured products ranging from semiconductors to drinking water.

需要維持消毒劑殘留以防止生物膜在 38 ppb 或以下時過度生長,以確保 RO 膜的預期壽命,這顯示有必要在如此低的濃度下準確監測餘氯。超低濃度 (Ultra Low Range) CL17sc 氯自動分析儀 採用比色法測量總氯殘留量,其檢測下限 (LOD) 為 8 ppb,具有無與倫比的精確度。

每 150 秒報告一次的準確氯讀數將呈現脫氯過程的完整情況,偵測純水氯濃度是否超出設定限值,並有助於正確管理 RO 膜。ULR CL17sc 氯線上分析儀的累積氯計數器™功能可計算並於分析儀螢幕上顯示在設定時間有多少氯通過薄膜。

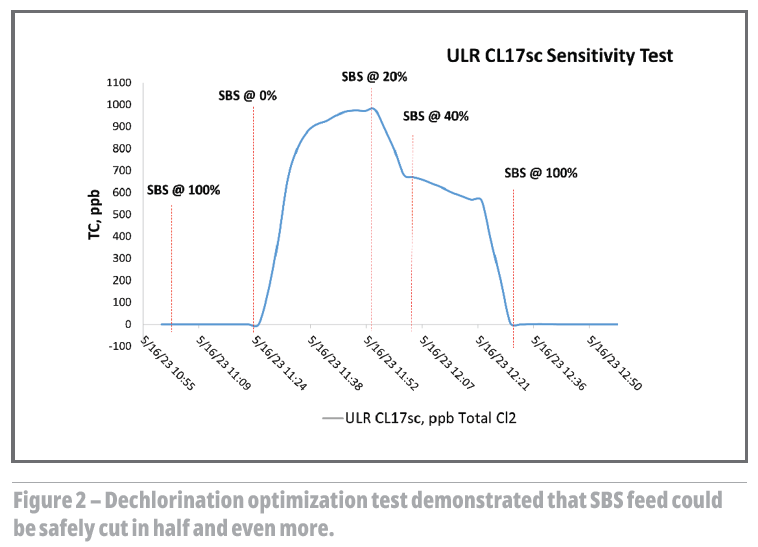

The personnel knew they were overfeeding SBS, however could not quantify it using standard instrumentation, therefore used a Hach DR1300 FL handheld using fluorometric method to verify ULR chlorine and sulfite concentrations. A test involving ULR CL17sc process analyzer was conducted to quantify chlorine response and optimize the SBS feed. The test results (Figure 2) showed that optimal SBS feed to maintain ~40 ppb residual chlorine would be at 60-70% of the current rate, which would provide significant chemical cost savings justifying implementation of the ULR CL17sc analyzer.

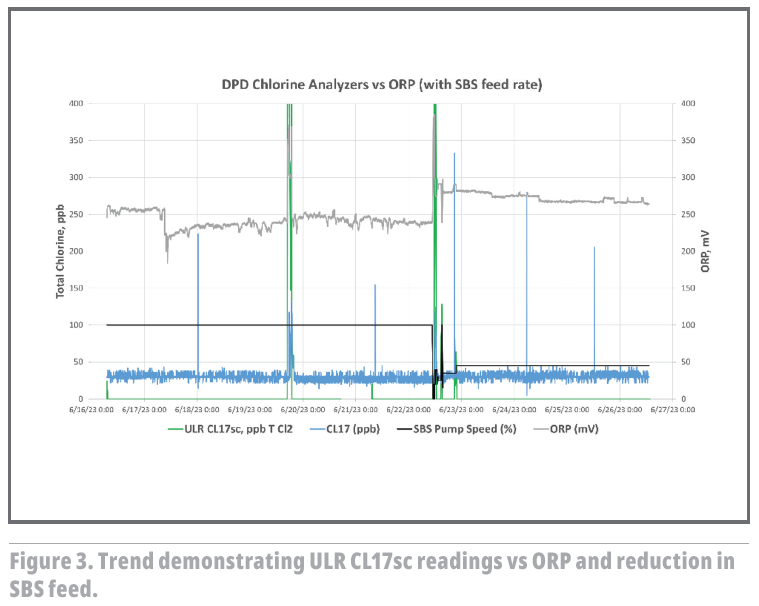

After the test, the UPW facility management decided to halve the SBS feed rate (Figure 3) and purchased the analyzer.

操作人員遇到過量投放 SBS(sodium bisulfite,亞硫酸氫鈉)的狀況,但無法使用一般分析儀器進行量化監測,因此使用了Hach DR1300 FL 手持式(超低濃度)餘氯、總氯和亞硫酸鹽分析光學比色計 來驗證超低濃度氯和亞硫酸鹽濃度。並使用 ULR CL17sc 超低濃度氯線上分析儀 進行監測,以量化氯反應並優化 SBS的投放量。測試結果(圖 2)顯示,為維持大約 40 ppb 餘氯濃度,最佳 SBS 投放量約為目前速度的 60-70%,這將顯著節省化學成本,同時也證明了採用 ULR CL17sc 超低濃度氯線上分析儀的合理性。

After the test, the UPW facility management decided to halve the SBS feed rate (Figure 3) and purchased the analyzer.

操作人員遇到過量投放 SBS(sodium bisulfite,亞硫酸氫鈉)的狀況,但無法使用一般分析儀器進行量化監測,因此使用了Hach DR1300 FL 手持式(超低濃度)餘氯、總氯和亞硫酸鹽分析光學比色計 來驗證超低濃度氯和亞硫酸鹽濃度。並使用 ULR CL17sc 超低濃度氯線上分析儀 進行監測,以量化氯反應並優化 SBS的投放量。測試結果(圖 2)顯示,為維持大約 40 ppb 餘氯濃度,最佳 SBS 投放量約為目前速度的 60-70%,這將顯著節省化學成本,同時也證明了採用 ULR CL17sc 超低濃度氯線上分析儀的合理性。

經過測試後,超純水設施管理人員決定將 SBS投放速率減半(圖 3)並採購了超低濃度氯線上分析儀。

Outcomes 結果

Application of the ULR CL17sc in combination with DR1300 FL handheld fluorometer helped to keep the SBS feed under tighter control.As demonstrated by the conducted field testing, implementation of ULR CL17sc for monitoring of RO feedwater dechlorinated with SBS can save enough money only on the chemicals to justify purchase of the analyzer.

The indirect cost saving encompassing prolonged life of the RO membranes, assurance of produced water quality, overall decrease of maintenance efforts would provide additional reasons to adopt new analytical instrumentation for process optimization in UPW production.

The ULR CL17sc instrument will provide highly accurate direct chlorine measurements at minimal maintenance efforts supporting all chemical and labor cost savings and projecting the full ROI in one to two years on average.

結合使用 ULR CL17sc 超低濃度氯線上分析儀 以及 DR1300 FL 手持式(超低濃度)餘氯、總氯和亞硫酸鹽分析光學比色計 協助對 SBS 進料進行更嚴格的控制。

現場測試證明,使用 ULR CL17sc超低濃度氯線上分析儀監測以 SBS 脫氯的 RO 給水,有效協助降低化學品投放量與節省成本,達到節約與環保,證明購買此分析儀之適當性。

間接節省成本包括延長逆滲透膜的使用壽命、確保產水品質、整體減少人力維護工作量。

ULR CL17sc超低濃度氯線上分析儀以最少的維護工作量和高精密度技術直接自動監測純水氯濃度,節省所有化學品投放量以及人工成本。

間接節省成本包括延長逆滲透膜的使用壽命、確保產水品質、整體減少人力維護工作量。

ULR CL17sc超低濃度氯線上分析儀以最少的維護工作量和高精密度技術直接自動監測純水氯濃度,節省所有化學品投放量以及人工成本。

Source : Hach US