歐洲應用實績>生技製藥廠的一站式污水監測方案

Sustainable wastewater monitoring for a pharmaceutical company

Source : Hach Europe

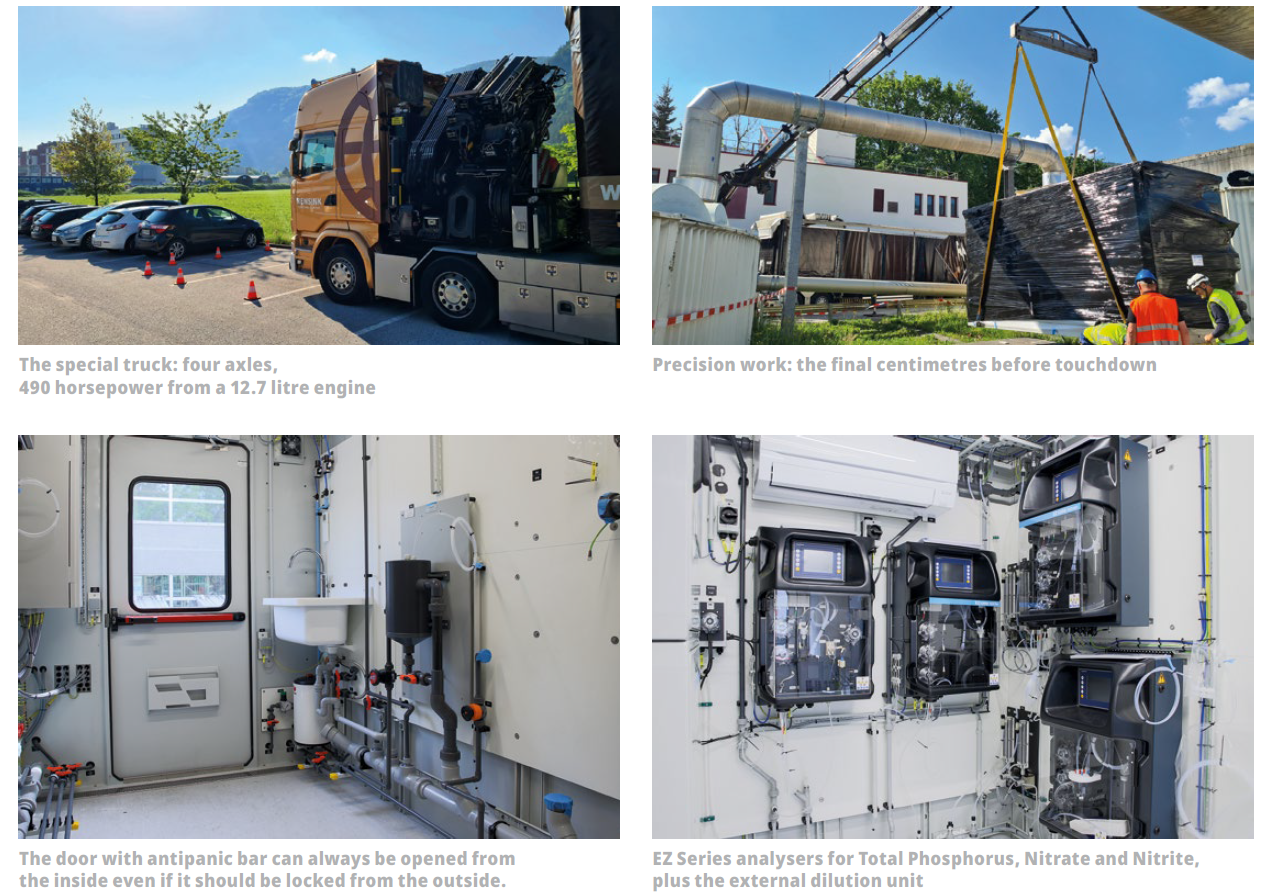

A loading crane is used to lift the finished analyser shelter directly to its location – across a pipeline at a height of 6.5 m onto a concrete foundation that starts 6.7 m away from the driveway.

Summary

Veolia Industries Austria operates the wastewater treatment plant of a pharmaceutical company in Kundl, Tyrol. Recently, the industrial site was opened to other companies as well.

Due to changing production processes, the control of the wastewater treatment plant can be a challenge. If you look at the COD values, for example, the plant occasionally has to cope with up to 500,000 population equivalent values. The plant is a direct discharger into the nearby river Inn.

A new water rights notice and stricter requirements prompted the company to sustainably upgrade the wastewater treatment plant and convert it to membrane technology. As part of the project, additional measuring points and parameters were to be monitored and the process instrumentation modernised.

In cooperation with the local Hach® team and the plant in Nazareth, Belgium, a complete turnkey solution was installed that offers significantly improved conditions for employees and measurement technology.

Veolia Industries Austria operates the wastewater treatment plant of a pharmaceutical company in Kundl, Tyrol. Recently, the industrial site was opened to other companies as well.

Due to changing production processes, the control of the wastewater treatment plant can be a challenge. If you look at the COD values, for example, the plant occasionally has to cope with up to 500,000 population equivalent values. The plant is a direct discharger into the nearby river Inn.

A new water rights notice and stricter requirements prompted the company to sustainably upgrade the wastewater treatment plant and convert it to membrane technology. As part of the project, additional measuring points and parameters were to be monitored and the process instrumentation modernised.

In cooperation with the local Hach® team and the plant in Nazareth, Belgium, a complete turnkey solution was installed that offers significantly improved conditions for employees and measurement technology.

奧地利威立雅工業公司於蒂羅爾州昆德爾為一家製藥公司的污水處理廠提供運營服務。 近來,此工業區也向其他公司開放提供服務。

由於生產工藝的變化,污水處理廠的控制成為一個新挑戰。 例如 COD 值,污水處理廠有時必須處理高達 500,000 人口當量值。 而此處理廠處理過的水直接排放到鄰近因河。

新的水權通知和更嚴格的要求規範促使該公司對污水處理廠進行永續升級,並將其轉換為膜技術。 專案的其中一部分是需要監測額外的測量點和水質參數,並對線上儀器進行現代化改造。

經過與當地 Hach® 團隊和Hach比利時工廠合作,最終成功安裝完整一站式的監測站方案,明顯改善員工工作環境和量測技術。

由於生產工藝的變化,污水處理廠的控制成為一個新挑戰。 例如 COD 值,污水處理廠有時必須處理高達 500,000 人口當量值。 而此處理廠處理過的水直接排放到鄰近因河。

新的水權通知和更嚴格的要求規範促使該公司對污水處理廠進行永續升級,並將其轉換為膜技術。 專案的其中一部分是需要監測額外的測量點和水質參數,並對線上儀器進行現代化改造。

經過與當地 Hach® 團隊和Hach比利時工廠合作,最終成功安裝完整一站式的監測站方案,明顯改善員工工作環境和量測技術。

All sample and supply lines are connected.

Initial situation

For more than 25 years, analysers from various manufacturers have been in use at the plant to monitor ammonium, nitrate and phosphorus levels. The previous installation location is underground in the collector corridor between the reactors.

Lifecycle issues of the instrumentation as well as accelerated corrosion due to the unfavourable environment at the installation site gave reason to completely rethink the concept of online analytics and consider a container solution.

The large number of sampling points and the required process instruments, combined with the time pressure, proved to be so complex that the specialists from the Hach Integrated Systems department were brought on board.

Lifecycle issues of the instrumentation as well as accelerated corrosion due to the unfavourable environment at the installation site gave reason to completely rethink the concept of online analytics and consider a container solution.

The large number of sampling points and the required process instruments, combined with the time pressure, proved to be so complex that the specialists from the Hach Integrated Systems department were brought on board.

25年多來,此污水處理廠採用來自不同製造商的分析儀來監測銨、硝酸鹽和磷的濃度。 先前儀器的安裝位置位於反應器之間的收集器走廊的地下室。

基於儀器的生命週期問題以及由於安裝現場的不利環境而導致的加速腐蝕,團隊完全重新思考線上分析的概念並考慮監測站方案。

大量的採樣點和所需的線上儀器,再加上時間壓力,事實證明非常複雜,因此Hach系統整合部門的專家被邀請參與在規劃當中。

基於儀器的生命週期問題以及由於安裝現場的不利環境而導致的加速腐蝕,團隊完全重新思考線上分析的概念並考慮監測站方案。

大量的採樣點和所需的線上儀器,再加上時間壓力,事實證明非常複雜,因此Hach系統整合部門的專家被邀請參與在規劃當中。

Complete turnkey solution 完整一站式的監測站方案

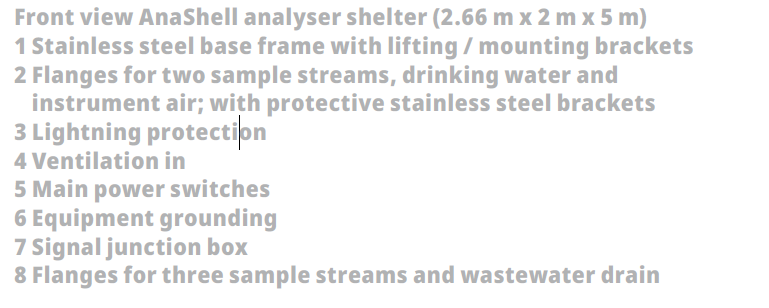

The team in Nazareth, Belgium, has been part of Hach since 2017 and has more than 30 years of experience in building analyser shelters for industrial and municipal customers.

The special requirements in this project:

• Five sample streams with different parameters

• Large number of process instruments and systems for sample preconditioning

• Integration of measuring technology already available at the customer

• Location of the installation site between pipelines

• Requirement: five months delivery time

The special requirements in this project:

• Five sample streams with different parameters

• Large number of process instruments and systems for sample preconditioning

• Integration of measuring technology already available at the customer

• Location of the installation site between pipelines

• Requirement: five months delivery time

Hach比利時的團隊擁有 30 多年的經驗為工業和民生客戶規劃建造線上分析儀監測站。

此專案之特殊要求:

• 具有不同水質參數的五個水樣流

• 大量用於樣品預處理的工藝儀器和系統

• 整合客戶已有的測量技術

• 安裝地點位於管道之間

• 交貨時間五個月

• 具有不同水質參數的五個水樣流

• 大量用於樣品預處理的工藝儀器和系統

• 整合客戶已有的測量技術

• 安裝地點位於管道之間

• 交貨時間五個月

Parameter & instruments 水質參數和對應的線上分析儀器

• 懸浮固體 Suspended solids: Solitax ts-line sc probe

• 銨 Ammonium: 2 Amtax sc analyzers

• 總有機碳 和總氮 TOC and Total Nitrogen: BioTector B7000 analyzer

• 總磷 Total Phosphorus: EZ7823 analyzer

• 亞硝酸鹽 Nitrite: EZ1028 analyzer

• 硝酸鹽 Nitrate: EZ1029 analyzer

• 懸浮固體 Suspended solids: Solitax ts-line sc probe

• 銨 Ammonium: 2 Amtax sc analyzers

• 總有機碳 和總氮 TOC and Total Nitrogen: BioTector B7000 analyzer

• 總磷 Total Phosphorus: EZ7823 analyzer

• 亞硝酸鹽 Nitrite: EZ1028 analyzer

• 硝酸鹽 Nitrate: EZ1029 analyzer

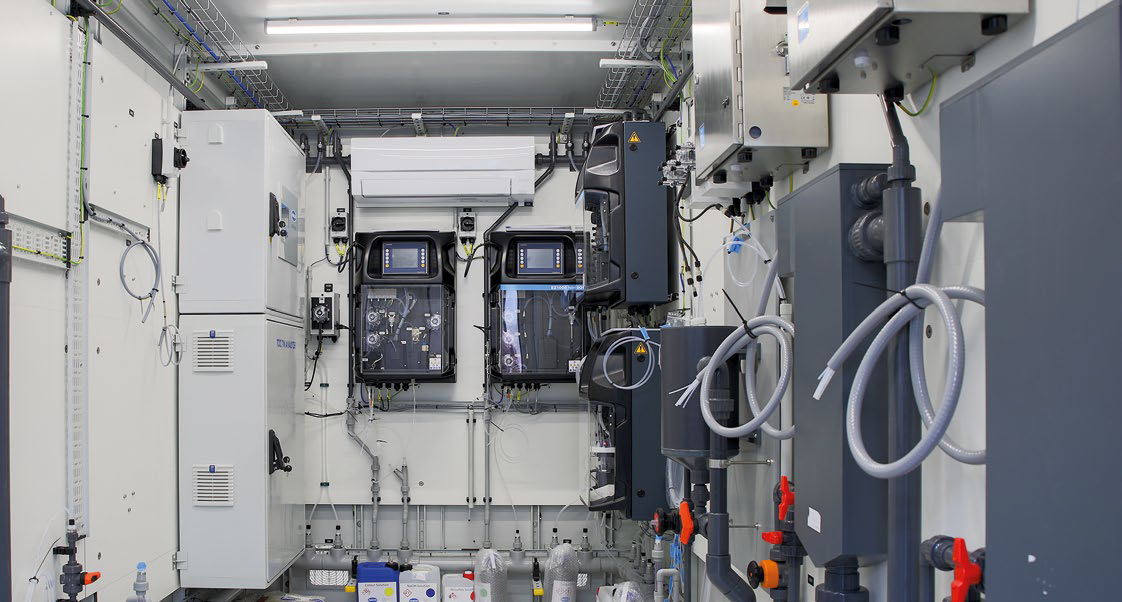

The Hach SC1000 controller, Amtax Ammonium analysers and Filtrax filtration systems purchased three years ago were included in the concept.

The old analysers from other manufacturers were replaced by new multi-channel devices from Hach. An EZ9750 dilution unit and a total of three Filtrax sc filtration systems are used for sample preconditioning.

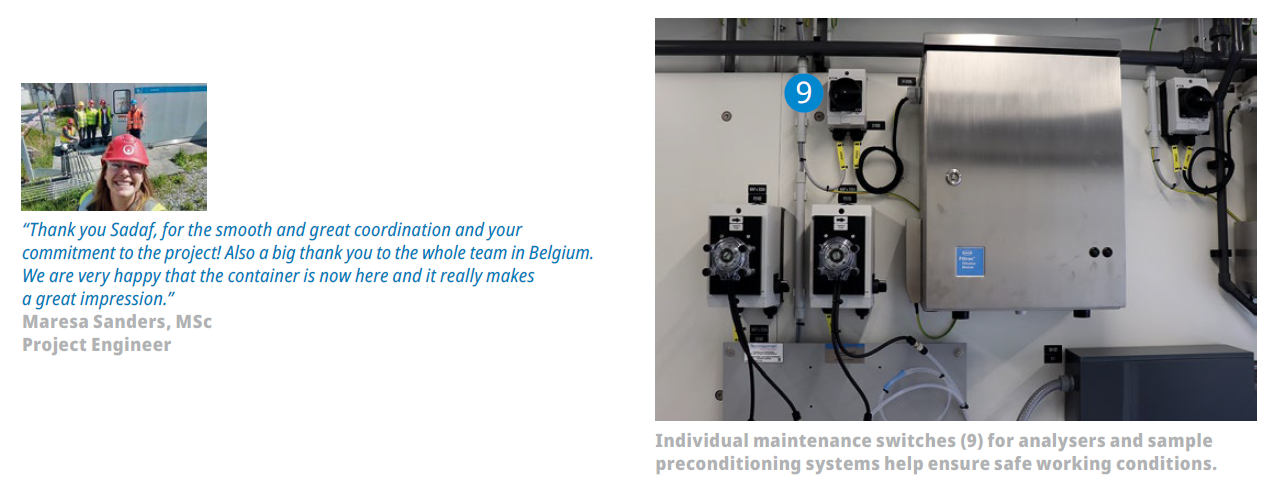

Each analyser is equipped with an individual maintenance switch. Next to the entrance door two main electrical power switches with lock position can be used to turn of power centrally if necessary.

The old analysers from other manufacturers were replaced by new multi-channel devices from Hach. An EZ9750 dilution unit and a total of three Filtrax sc filtration systems are used for sample preconditioning.

Each analyser is equipped with an individual maintenance switch. Next to the entrance door two main electrical power switches with lock position can be used to turn of power centrally if necessary.

監測儀器同時包括三年前購買的 Hach SC1000 水質感測控制主機、Amtax 銨線上分析儀和 Filtrax 過濾系統。

原有其他製造商的舊分析儀為Hach公司的新型多通道設備所取代。 一台 EZ9750 稀釋裝置和總共三個 Filtrax sc 過濾系統用於水樣預處理。

每個線上分析儀都配備有單獨的維護開關。 如有必要,入口門旁邊有兩個附鎖定位置的主電源開關,可用於集中關閉電源。

原有其他製造商的舊分析儀為Hach公司的新型多通道設備所取代。 一台 EZ9750 稀釋裝置和總共三個 Filtrax sc 過濾系統用於水樣預處理。

每個線上分析儀都配備有單獨的維護開關。 如有必要,入口門旁邊有兩個附鎖定位置的主電源開關,可用於集中關閉電源。

Conclusion

In future, the monitoring programme of the wastewater treatment plant will comprise five sample streams. The inflow and outflow of the reactors are analysed in order to further optimise the control system and safely comply with the new, stricter limits.

Veolia‘s employees and Hach‘s service technicians are happy to have an easily accessible, bright, clean and safe workplace for their work.

In future, the monitoring programme of the wastewater treatment plant will comprise five sample streams. The inflow and outflow of the reactors are analysed in order to further optimise the control system and safely comply with the new, stricter limits.

Veolia‘s employees and Hach‘s service technicians are happy to have an easily accessible, bright, clean and safe workplace for their work.

未來,污水處理廠的監測方案將包括五個水樣流。 分析反應器的進水和排水,以進一步優化控制系統並且安全地符合新的、更嚴格的排放標準。

威立雅的員工和Hach公司的服務技術人員很高興能有一個便利、明亮、清潔和安全的工作場所。

威立雅的員工和Hach公司的服務技術人員很高興能有一個便利、明亮、清潔和安全的工作場所。

The equipment is mounted on chemical-resistant HPL (high-pressure laminate) panels using modular mounting profiles. All connections are labelled and documented.