Aquafine OptiVenn Series 紫外線UV水處理系統

產品編號:

The OptiVenn series from Aquafine is a family of robust and flexible ultraviolet (UV) systems with advanced technology designed to meet the stringent requirements of pharmaceutical, food & beverage, microelectronics, and other industrial markets.

UV is a versatile, reliable approach to water treatment that addresses numerous concerns in industrial water applications. The OptiVenn series is used to treat E. coli and fecal coliform through microbial inactivation and to break down trace chemicals, including:

ozone ;

chlorine and chloramines ; and

total organic carbon (TOC).

The series consists of a 316L stainless steel chamber and 304 stainless steel control panel, and is equipped with a controller which provides control, monitoring and operational information in a single convenient location. The chamber and control panel are extremely compact and offer flexibility of installation to accommodate different skid designs or to be installed as a stand-alone UV system.

適用於工業環境水處理之紫外線 UV 殺菌系列 - 採用先進技術的紫外線消毒系統,適用於製藥、食品飲料、微電子和其他工業市場。分解微量化學物質;臭氧、氯和總有機碳。OptiVenn 系列可消毒 99.9% 的大腸桿菌和糞便大腸菌。

Accreditations* : UL, CE, NOM, NSF/ANSI/CAN 61&372, W270/KTW-BWGL:2022, DWI, ACS, EC 1935:2004, FDA CFR 21

UV is a versatile, reliable approach to water treatment that addresses numerous concerns in industrial water applications. The OptiVenn series is used to treat E. coli and fecal coliform through microbial inactivation and to break down trace chemicals, including:

ozone ;

chlorine and chloramines ; and

total organic carbon (TOC).

The series consists of a 316L stainless steel chamber and 304 stainless steel control panel, and is equipped with a controller which provides control, monitoring and operational information in a single convenient location. The chamber and control panel are extremely compact and offer flexibility of installation to accommodate different skid designs or to be installed as a stand-alone UV system.

適用於工業環境水處理之紫外線 UV 殺菌系列 - 採用先進技術的紫外線消毒系統,適用於製藥、食品飲料、微電子和其他工業市場。分解微量化學物質;臭氧、氯和總有機碳。OptiVenn 系列可消毒 99.9% 的大腸桿菌和糞便大腸菌。

Accreditations* : UL, CE, NOM, NSF/ANSI/CAN 61&372, W270/KTW-BWGL:2022, DWI, ACS, EC 1935:2004, FDA CFR 21

Key Features and Benefits :

Compact Footprint

Optimized chamber design and multiple lamp arrays enable cost-effective installation in extremely compact spaces.

Flexible Panel Installation

Can handle maximum flow capacity in minimal space. Its compact design allows it to be installed vertically or horizontally in restrictive spaces, thereby lowering installation costs.

High Performance UV Lamps

The low performance, high output (LPHO) lamps are approximately 3x more efficient than medium pressure lamps.

User-friendly Interface

Intuitive interface enables at-a-glance check status of system, including individual lamp status, UV intensity.

Guaranteed Performance and Comprehensive Warranty

When you use genuine Aquafine parts, we guarantee that your system will meet the disinfection requirement specified at purchase, provided that the system’s original design parameters haven’t changed (e.g., flow rate, UV transmittance) and maintenance is completed per the UV system's O&M manual.

Local Service, Global Support

Our comprehensive network of certified service providers offers ongoing maintenance programs and fast response for service and spare parts.

Flexible Chamber Requires Less Space

- An internal baffle and an anti-vibration mechanism optimize performance, support quartz sleeves and ensure reliable system performance even at high flow rates

- Can be installed with the chamber easily rotated to one of 4 different angles with no special customization required, reducing pipework, space, and installation cost.

Universal Control Panel Provides Installation Flexibility

- All UV systems have a stainless-steel control panel designed to provide maximum installation flexibility and fit within stringent space requirements

- All control panels are compliant with the -following electrical codes: cULus (Canada, USA), CE (Europe)

Versatility Built Into Our Design

- The panel can be mounted in various locations to optimize the use of space, especially for frame mounted designs

- The small and medium control panels can be mounted on top of, in front of, or remotely (up to 15 feet apart) from the cylinder

- The location of the panel can be easily changed

Advantages of Using UV in TOC Reduction :

Small footprint

Modular skid designs

Can operate indoor or outdoor installations

Low operational and maintenance costs

Application-specific reactor design

Engineered to meet or exceed < 1ppb TOC Specifications

Small footprint

Modular skid designs

Can operate indoor or outdoor installations

Low operational and maintenance costs

Application-specific reactor design

Engineered to meet or exceed < 1ppb TOC Specifications

Aquafine TOC reduction systems have the flexibility to serve indoor or outdoor installations and are available in modular skid designs. The systems are installed in critical applications around the world where meeting stringent criteria of the cGMP and full acceptance by the FDA are mandatory.

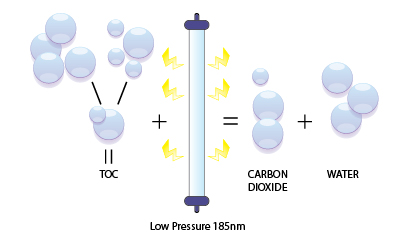

How UV and TOC Reduction Works

Aquafine TOC reduction systems harnesses UV light in a 185 nanometer wavelength. This powerful energy promotes the formation of free radicals, leading to the oxidation of organics into CO2 (carbon) and H2O (water) molecules. TOCs are reduced and the oxidation is complete.

Aquafine TOC reduction systems harnesses UV light in a 185 nanometer wavelength. This powerful energy promotes the formation of free radicals, leading to the oxidation of organics into CO2 (carbon) and H2O (water) molecules. TOCs are reduced and the oxidation is complete.