Pulp & Paper Industry 紙漿與造紙工業

Save Energy, Water and Costs 節省能源、水資源和成本

Gain continuous control over your pulp and paper manufacturing process.

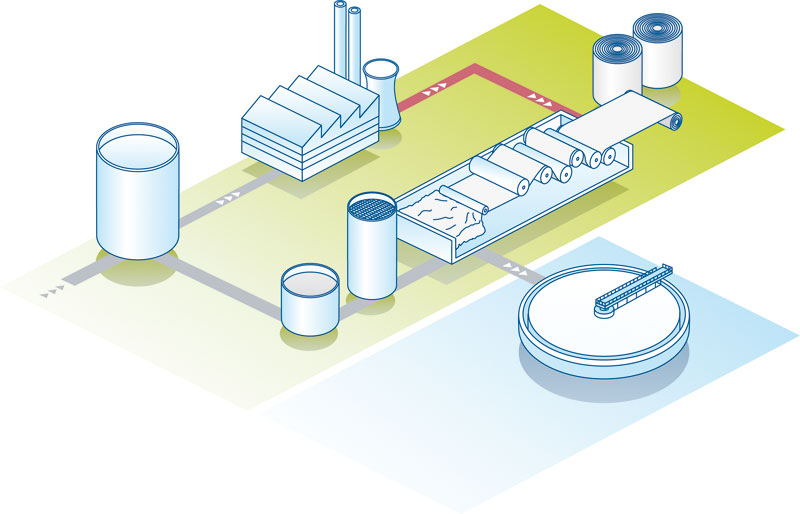

The pulp and paper industry is one of the largest industrial consumers of water, requiring 64,000 litres per ton of paper. Aside from wood fibers, water is the most important raw material in the pulp or paper mill. Simply put, pulp and paper manufacturing is impossible without water at every step of the production process—in specific tasks from pulping and bleaching to slurry dilution and fabric showers, in steam and power production for thermal and mechanical processes, as well as general operation uses such as materials transport and equipment cleaning.

Hach® offers comprehensive water analysis solutions to paper mills, including manufacturers of corrugated paper, corrugated cardboard, tissue mills, kraft mills, and non-woven manufacturers of products such as baby diapers, disinfection wipes and more. Despite the broad range of paper product applications, the entire pulp and paper industry shares two main goals when it comes to water use: conserve fresh water by reusing as much process water as possible, and treat wastewater to comply with regulations and protect local resources. To accomplish this, having reliable tools and data is key.

From laboratory analysis to process solutions, Hach’s accurate, easy-to-maintain instrumentation, comprehensive test kits and high-quality prepared reagents are based on nearly a century of innovation and a desire to provide the simplest way to results pulp and paper companies can trust.

紙漿和造紙工業是極大的工業耗水產業之一,每噸紙需水 64,000 公升。除了木纖維之外,水是紙漿或造紙廠中最重要的原料。紙漿和造紙生產過程的每一步都需要水 - 從製漿和漂白到漿料稀釋和織物噴淋的特定任務,用於熱力和機械過程的蒸汽和電力生產,以及一般操作用途例如物料運輸和設備清潔。

Hach® 為造紙廠提供全面的水分析解決方案,包括瓦楞紙、瓦楞紙板製造商、衛生紙廠、牛皮紙廠以及嬰兒尿布、消毒濕巾等產品的不織布製造商。儘管紙產品應用廣泛,但整個製漿造紙行業在用水方面有兩個主要目標:透過重複利用盡可能多的製程水來節約淡水,並處理污水以符合法規標準並保護當地資源。要實現這一目標,擁有可靠的工具和數據是關鍵。

從實驗室分析到線上監測方案,Hach準確並容易維護的分析儀器、測試套組和預製試劑,致力於提供最簡單的方法來協助紙漿和造紙公司取得可靠分析數據。

Featured Applications for the Paper and Pulp Industry 主要應用

Water Supply 供水

Monitor and control the microbial content of the raw water coming into your plant to minimize expensive post-input treatment processes and protect vital equipment.

Monitor and control the microbial content of the raw water coming into your plant to minimize expensive post-input treatment processes and protect vital equipment.

Steam and Power 蒸汽與電力

Keeping microbial contaminants out of your system and away from equipment like shower bars, paper-making fabrics, rolls and vacuum elements helps you keep your production online and your costs low.

Wastewater Treatment 污水處理

From Total Organic Carbon (TOC) and Chemical Oxygen Demand (COD) content to phosphorous, bacteriological and specialized contaminants, Hach provides the compliance monitoring you need to maintain a sustainable environmental impact and remain compliant with all applicable regulations.

Water Supply Conditioning 供水調節

Because more than 90% of water used in the paper making process is sourced from the local environment, incoming water quality, including organic content, chemistry, dissolved oxygen and flow, varies with the weather and the seasons. Confident measurement and management of fresh water enables efficient, cost-effective production of high quality pulp and paper, whereas poor or unknown water quality creates costly consequences. Real-time analysis starting at raw water intake enables pulp and paper mills to:

- Optimise biocide/disinfectant dosage

- Detect changes to incoming water quality and take preventive action (e.g. the addition of chlorine to minimise bacterial and slime growth)

- Monitor plant efficiency and production performance

- Guard against in-plant corrosion and in-plant scale

- Check potential of non-ionic inorganics to cause in-plant deposits

- Assure effective filtration

How to Measure 量測儀器 :

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

CEL Water Conditioning Laboratory

Deluxe Water Conditioning Demonstration Kit

Pocket Colorimeter

CL17 Colorimetric Chlorine Analyzer

CLF10 Free Chlorine Analyzer

EZ1024 Iron Analyser Fe(II+III)

EZ1025 Manganese Analyzer Mn(II)

EZ 2303 Total Manganese Analyzer

EZ 2305 Total Iron Analyzer

EZ4004 Total Alkalinity Analyzer

EZ4041 Total Hardness Analyzer

EZ 5001 Free Alkalinity Analyzer

PHD sc Differential pH Sensors

LuminUltra ATP Test Kits

SP 510 Hardness Monitor

Solitax SC Turbidity Immersion Probes

SS7 sc High Range Turbidimeter

TU5300/400 Turbidimeters

9610 sc Silica Analyzer

BioTector B3500e TOC Analyzer

CEL Water Conditioning Laboratory

Deluxe Water Conditioning Demonstration Kit

Pocket Colorimeter

CL17 Colorimetric Chlorine Analyzer

CLF10 Free Chlorine Analyzer

EZ1024 Iron Analyser Fe(II+III)

EZ1025 Manganese Analyzer Mn(II)

EZ 2303 Total Manganese Analyzer

EZ 2305 Total Iron Analyzer

EZ4004 Total Alkalinity Analyzer

EZ4041 Total Hardness Analyzer

EZ 5001 Free Alkalinity Analyzer

PHD sc Differential pH Sensors

LuminUltra ATP Test Kits

SP 510 Hardness Monitor

Solitax SC Turbidity Immersion Probes

SS7 sc High Range Turbidimeter

TU5300/400 Turbidimeters

9610 sc Silica Analyzer

Steam & Power 蒸氣動力

Because of the energy consumed to heat, pump and circulate water, and because of the key machinery at risk of scale and corrosion, careful analytics at this stage is a high-value priority. Additionally, because water is demineralised, treated and reused throughout the papermill, changes to parameters during steam generation have costly repercussions: boiler feed water must be purified to minimise corrosion, while treated steam condensate can be reused in the steam system. Continuous monitoring enables your operation to make informed process decisions and manage costs by:

- Monitoring oxygen scavengers and controlling oxygen scavenger dosing to avoid corrosion as well as overdosing

- Controlling the addition of phosphate to reduce corrosion and deposits

- Avoiding damage to turbines and tubes caused by precipitates

- Detecting efficiency loss in ion exchangers or membrane systems used for pre-treatment

How to Measure 量測儀器 :

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

8362 sc High purity pH and ORP/Redox Sensor

9586 Oxygen Scavenger Analyzer

9523 Specific and Cationic Conductivity Analyzer

9525 Degassed Cationic Conductivity Analyzer

TU5 Turbidimeter

NA5600sc Sodium Analyzer

3400 Digital Contacting Conductivity Sensors

3400 Analog Contacting Conductivity Sensors

5500 sc Silica Analyzer

5500 sc Phosphate Analyzer

EZ1005 Chloride Analyzer

EZ1031 Phosphate Analyzer

EZ5005 Total Hardness + Total / Free Alkalinity Analyzer

EZ7300 Microbial Load ATP Analyzer

BioTector B3500e TOC Analyzer

8362 sc High purity pH and ORP/Redox Sensor

9586 Oxygen Scavenger Analyzer

9523 Specific and Cationic Conductivity Analyzer

9525 Degassed Cationic Conductivity Analyzer

TU5 Turbidimeter

NA5600sc Sodium Analyzer

3400 Digital Contacting Conductivity Sensors

3400 Analog Contacting Conductivity Sensors

5500 sc Silica Analyzer

5500 sc Phosphate Analyzer

EZ1005 Chloride Analyzer

EZ1031 Phosphate Analyzer

EZ5005 Total Hardness + Total / Free Alkalinity Analyzer

EZ7300 Microbial Load ATP Analyzer

Paper Machine Wet End Operations Monitoring 造紙機器濕部操作監控

Measuring at the approach system and at the whitewater loops of the paper machine helps ensure optimum operation to achieve the specifications of the paper pulp and paper grade produced, as well as recuperation of raw stock/energy from the saveall. Approach system and whitewater loops quality analysis enables:

- Monitoring for optimal chemical reactions at the wet end and formation of the sheet

- Controlling coagulant and polymer dosage

- Online calculation of the first pass retention

- Optimisation of the saveall operation for water, heat, chemicals, filler, and fiber recovery

- Early detection of calcium and magnesium that shorten the life of costly equipment

- Fast microbiology analysis to monitor biocide program efficiency

How to Measure 量測儀器 :

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

TSS sc Sensors

RTC-ST Sludge Thickening Software

PHD pH and ORP/Redox Differential Sensors

LuminUltra ATP Test Kits

Pocket Colorimeter

Intellical ORP/Redox/pH Sensors

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

TSS sc Sensors

RTC-ST Sludge Thickening Software

PHD pH and ORP/Redox Differential Sensors

LuminUltra ATP Test Kits

Pocket Colorimeter

Intellical ORP/Redox/pH Sensors

Primary & Secondary Wastewater Treatment 一級和二級污水處理

Because 90% of the water used in a paper mill is returned to its source, meticulous water treatment before discharge is essential. Assure pulp and paper effluent complies with regulations by monitoring and optimising primary and secondary wastewater treatment. Save energy and chemicals with real-time adjustments based on accurate data. Hach instrumentation and solutions enable:

- Optimisation of primary/secondary clarification

- Optimisation of flocculation and sludge dehydration process

- Control of activated sludge retention time for foam and filamenteous protection

- Dosage control and optimisation of nitrogen and phosphorus

- Monitoring of the biomass “health” with ATP measurement

- Real-time monitoring of effluent regulated parameters

- Wastewater plant data management for analysis and automatic reporting

How to Measure 量測儀器 :

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

AMTAX sc Ammonium Analyzer

PHOSPHAX sc Phosphate Analyzer

Differential pH Digital Sensors

UVAS plus sc UV Probe Sensor

LDO sc Luminescent Dissolved Oxygen Sensor

TSSsc Turbidity and Suspended Solids Sensors

Solitax sc Turbidity and Suspended Solids Probes

Filtrax Sample filtration system

HQ440D Laboratory pH Meter Package

Grab Samplers

Portable Samplers

RTC-SD Sludge Dewatering Software

RTC-SRT Aeration Process Software

RTC-DAF Software

RTC-DOS Nutrient Dosing Software

WIMS Water Information Management Solution

NITRATAX Nitrate Sensors

LuminUltra ATP Test Kits

Sonatax Sludge Level Sensor

NX7500 UV Sensors

EZ1003 Ammonium Analyzer

EZ7000 Chemical Oxygen Demand Analyzer (COD, Dichromate Method)

EZ7200 Volatile Fatty Acids (VFA) Analyzer

EZ7700 Total Nitrogen Analyzer

EZ7800 Total Phosphorus Analyzer

EZ7900 Toxicity Analyzer

BioTector B7000i TOC Analyzer

BioTector B3500e TOC Analyzer

AMTAX sc Ammonium Analyzer

PHOSPHAX sc Phosphate Analyzer

Differential pH Digital Sensors

UVAS plus sc UV Probe Sensor

LDO sc Luminescent Dissolved Oxygen Sensor

TSSsc Turbidity and Suspended Solids Sensors

Solitax sc Turbidity and Suspended Solids Probes

Filtrax Sample filtration system

HQ440D Laboratory pH Meter Package

Grab Samplers

Portable Samplers

RTC-SD Sludge Dewatering Software

RTC-SRT Aeration Process Software

RTC-DAF Software

RTC-DOS Nutrient Dosing Software

WIMS Water Information Management Solution

NITRATAX Nitrate Sensors

LuminUltra ATP Test Kits

Sonatax Sludge Level Sensor

NX7500 UV Sensors

EZ1003 Ammonium Analyzer

EZ7000 Chemical Oxygen Demand Analyzer (COD, Dichromate Method)

EZ7200 Volatile Fatty Acids (VFA) Analyzer

EZ7700 Total Nitrogen Analyzer

EZ7800 Total Phosphorus Analyzer

EZ7900 Toxicity Analyzer